ULTRAKOTE UVSeal

UltraKote UVSeal is a single-pack, high UV resistant, moisture-curing aliphatic polyurethane concrete coating product. When cured, UVSeal produces a high gloss, extremely tough and hardwearing film with excellent resistance to UV and yellowing.

Advantage of Ultrakote UVSeal

- The biggest advantage of Ultrakote UV Seal Polyurethane over other similar products is that it is a single-pack product and doesn’t require mixing

- Excellent hot tyre pick-up resistance, which makes it a great choice for garage epoxy floors

- Excellent wear and abrasion resistance.

- Excellent UV resistance and suitable for both interior and exterior surfaces

- Produces smooth and glossy finish with good aesthetics and easy to clean

- slip resistance floor finishes can be achieved by adding anti-slip media to the coating system.

- Easy application by brush, roller, or low pressure spray equipment.

- Available in a CLEAR GLOSS only.

Areas of use

- Garage floors

- Warehouses

- Patios

- Balconies

- Showrooms

- Shops

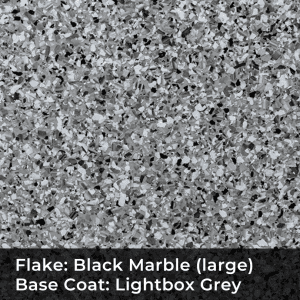

- Flake flooring

UltraKote UVSeal Packaging /Kit Size

UK UV Seal is supplied in 10 litre drum.

Special pricing applies to orders over 10 drums /100 litres.

Recommended Preparation Method

Preparation is the key to achieving a long-lasting floor-coating system

Diamond grinding is recommended method of preparing new & old substrates prior to applying Ultrakote UVSeal

The purpose behind concrete grinding is to remove any flaking paint and other types of contamination to achieve a clean surface as well as remove any sealer or curing agent and open concrete pores allowing 1st coat of UltraKote UVSeal to penetrate deep into the surface and seal the floor.

Concrete is to be cured for a minimum of 28 days, must be diamond grinded and free from any imperfections that may cause the system to fail. Remove all surface laitance, oil, grease or any defective concrete that will reduce the bond of UVSeal. If concrete cannot be grinded, the following steps may be taken however may reduce the success for the coating.

Newly applied concrete

Concrete is to be free from all contaminants, i.e. grease, oil, loose particles and cleaning agents and 28 days old before applying coating to the floor.

Older Concrete

Prepare the concrete with a diluted surfactant to degrease and wash with a high-pressure cleaner. Make sure all degreasing agent is removed, and the concrete is dry, before proceeding to the next step.

- Acid etch concrete with hydrochloric acid (HCL) Dilution rate: 1L HCL to 20L water (always add the water first and pour acid into the water to avoid splashing of the acid). Smoother concrete will require a higher concentration of acid.

- Apply evenly over the concrete with a plastic watering bucket. Pressure wash with water immediately after (before the acid dries).

- Allow the surface to dry completely before sealing.

- Only apply UK-PU40 if the surface is dry and contaminate-free.

- UK-PU40 is supplied in ready-to-use pails. Please homogenize the product by mixing it with a LOW SPEED mechanical drill before application.

Coating over previously coated surfaces

Important note: Apply a test patch over a small section and allow to dry to assure it is compatible with the existing coating

- Sanding over the surface using 150+ grit sanding discs attached to a floor sanding machine.

- Vacuum dust and solvent and wipe over the coating using methylated spirit or GP thinners

- Apply 2 roll coats of UVSeal over the surface

Recommended diamond tooling grits to prepare the floor prior to applying Ultrakote UVSEAL;

UltraKote UVSeal is a medium solids Polyurethane finish and will require a finer grind using 80 – 120 Grit diamond tooling.

Consumption Coverage Guide | 10kg Pail

Sealing over full flake surface

| Area Size | 1st coat | 2nd Coat | Recommended Minimum no of coats | Required no of drums |

| Up to 25m2 | 6 Litres | 4 Litres | Two coats | One Drum |

| 25 – 50m2 | 6 – 10 L | 6 – 10 L | Two coats | Two Drums |

| 50 – 80m2 | 10 – 15 L | 10 – 15 L | Two coats | Three Drums |

Sealing over PARTIAL FLAKE and bare Concrete Floors

| Area Size | 1st coat | 2nd Coat | Recommended Minimum no of coats | Required no of drums |

| Up to 30m2 | 5 Litres | 5 Litres | Two coats | One Drum |

| 30 – 60m2 | 5 – 10 L | 5 – 10 L | Two coats | Two Drums |

| 60 – 90m2 | 10 – 15 L | 10 -15 L | Two coats | Three Drums |

Notes

- Please use the table above as a guide only, as the consumption could depend on the application method/style and porosity of the surface.

- Applying additional coats to the floors subject to heavy traffic is recommended

- Consider thinning down the first coat by adding 5% of general-purpose thinners when applying the product over bare concrete surfaces.

- A slip-resistance surface covering can be achieved by adding anti-slip media

Guide to achieving R or P rated slip resistance floor covering using different grit anti-slip media

Anti-slip media may change the look of the finish and test a small area before applying UVSeal + Anti slip media to larger areas

To achieve P3 or R10 slip rating – 60 Grit Aluminium oxide

To achieve P4 or R11 slip rating – 46 Grit Aluminium oxide

To achieve P5 Or R12 slip rating – 30 grit Aluminium oxide

Document Download

Click on the tiles below to download ULTRAKOTE UVSeal Technical Data Sheets and Safety Data Sheets.

|

|

Contact Sydney Industrial Coatings for any inquiries.

Ashley Patterson –

Easy to use with good gloss levels

Tariq Ajram –

Well priced product and value for moeny!

Jamie Taylor –

Excellent an outstanding product that offers excellent value, coupled with its easy application process!