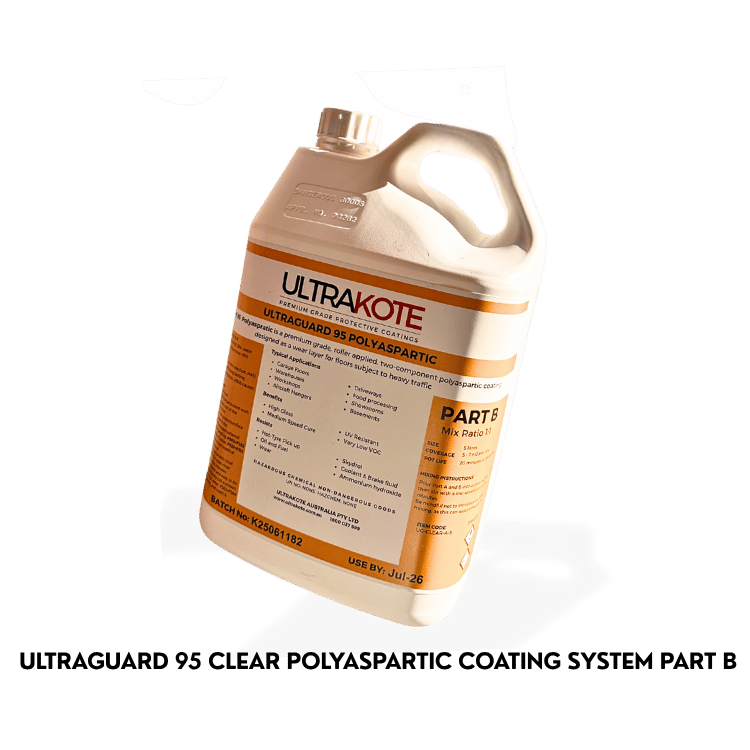

Ultra Guard 95 Clear Polyaspartic Coating System

UltraKote’s UltraGuard 95 Polyaspartic is a premium, state-of-the-art two-component clear polyaspartic floor coating system designed to deliver decorative appeal and long-lasting durability on a wide range of surfaces. Formulated with advanced aliphatic chemistry, it provides superior UV stability and colour retention—outperforming traditional epoxy coatings when exposed to sunlight. With a simple 1:1 mix ratio and generous pot life, it can be applied easily using standard flooring tools, making it suitable for many environments.

1 Litre Colour Packs

(Grey, Black, and White) are sold separately at $70.00 each.

Features & Benefits

- UV Resistance – No breakdown when direct in sunlight

- Non-yellowing – Colour stable when direct in sunlight

- High solids – 95% solids able to achieve up to 300um DFT in one coat

- Good chemical resistance – resistant to most household and commercial chemicals

- Excellent dry slip resistance

- Elastomeric behaviour: remains flexible at low temperatures

- Low odour and VOC

- Can be used with anti-slip powders or flaking options

TYPICAL USES

Ultrakote UltraGuard 95 Polyaspartic Clear is perfect for enhancing the durability and aesthetic appeal of concrete floors, countertops, and similar spaces, including garage floors, laboratories, restaurants, aeroplane hangars, entryways, lobbies, and warehouses. Its seamless application conforms effortlessly to any shape and size.

AREAS OF USE

- Garage Floors

- Warehouses

- Showrooms

- Driveways

- Patios

- Aircraft Hangars

- Mechanical workshops

- Warehouse Floors

- Car parks

- Hospitals

- Shopping Centers

- Commercial Kitchens

- salons

- mechanic workshops

- food courts etc..

PREPARATION

- Check that the surface to be coated is stable and free of any loose grit, sand, dirt, oil and grease.

- Thoroughly clean and ensure the surface to be coated is completely dry.

New Slabs: Check moisture content and ensure concrete has been cured for at least 60 days. Ensure concrete is clean and free of any loose bits before application. If slab has been trowelled smooth finished it will require mechanical grind to ensure adhesion.

Old Slabs: Remove any old coatings by grinding surface and have surface finished at least 60 to 100 grit before application of UltraGuard 95. Surface must be clean, sound, smooth and dust-free as well as oil-free.

- If primer is required, please ensure test area is conducted to ensure compatibility with primer.

- If applying onto substrates such as vinyl, terrazzo, or polished concrete it is recommended to test adhesion.

- It is always recommended to check adhesion to substrate before application.

Note: All substrates should have a mechanical key before application of the first coat. It’s recommended to at least finish at 60–80 grit if direct to concrete or 100–150 grit if coating on top of a coating system.

APPLICATION CONDITIONS

- Do not apply UltraGuard 95 when ambient and/or surface temperature is below 0°C or above 30°C.

- Do not apply UltraGuard 95 if relative humidity is more than 80%.

- Do not apply UltraGuard 95 if moisture content of substrate is more than 5%.

Optimum application conditions are between 20°C and 25°C with a relative humidity of 35% to 50%.

APPLICATION

Mixing UltraGuard 95 Part A to Part B equally 1:1 by volume is required. Please ensure mixing is performed efficiently although be careful not to incorporate too much aeration into the mix. Typically, hand paddle mixing is the preferred method. UltraGuard 95 is a slow to moderate reacting material which starts the reaction process once both parts are mixed (refer to drying properties – pot life page 1), therefore it can be mixed up to 10 L at a time without the risk of the material gelling in the pot. Please note that product will need to be applied within the first 30 minutes to 1 hour to minimize the risk of gel.

Application of UltraGuard 95 is done using a 10mm to 12mm nap mohair or microfiber roller, or a light T-Bar applicator tool.

It is then recommended to pour the mix onto the floor in a ribbon or pooling method, then spread by roller or applicator tool. The product is then finished by rolling to end joint, seams or coating line. Edges are brushed-in using a thick bristle paint brush – the material is not poured around the edges but can be dipped into a paint container.

COVERAGE

Approximately 6–10 m² per L of mixed material to achieve 100 to 300-micron dry film thickness (depending on substrate porosity).

DILUTING

Maximum dilution rate of 7% by volume of Xylene. Please ensure xylene is moisture-free otherwise pot-life and working time will be greatly affected.

RECOATING INSTRUCTIONS

Recoating can occur after application of first coat at 5–6 hrs at 25°C and 35% R.H., although it has a maximum recoat window of 18 hours at 25°C and 35% R.H. If this window is missed, it is required to cut back first coat with at least 100–180 grit abrasive before next coat application.

DECORATIVE FLAKE

Decorative flake can be broadcast onto the first coat within the open time of 1.5 hours at 25°C and 35% R.H. Once broadcasted flake coat has dried, remove excess and lock in the system with a final clear coat.

CLEAN UP

Reusable tools should be cleaned carefully with Xylene before curing.

ADDITIONAL INFORMATION

UltraKote UltraGuard Polyaspartic is trusted for its durability, fast installation, and wide range of applications across both commercial and residential environments. Commonly used in garage floors, warehouses, showrooms, food processing spaces, basements, driveways, aircraft hangars, and workshops, this polyaspartic floor coating is easy to maintain while providing exceptional strength and aesthetics. Its topcoat resists corrosion and weathering, staying non-yellowing even under direct UV exposure.

With rapid drying times, UltraKote UltraGuard 95 reduces downtime significantly when compared to other coatings. It supports decorative options like paint flakes and quartz chips, making it suitable for various interior and exterior concrete surfaces.

Contact Sydney Industrial Coatings for more information.

Reviews

There are no reviews yet.