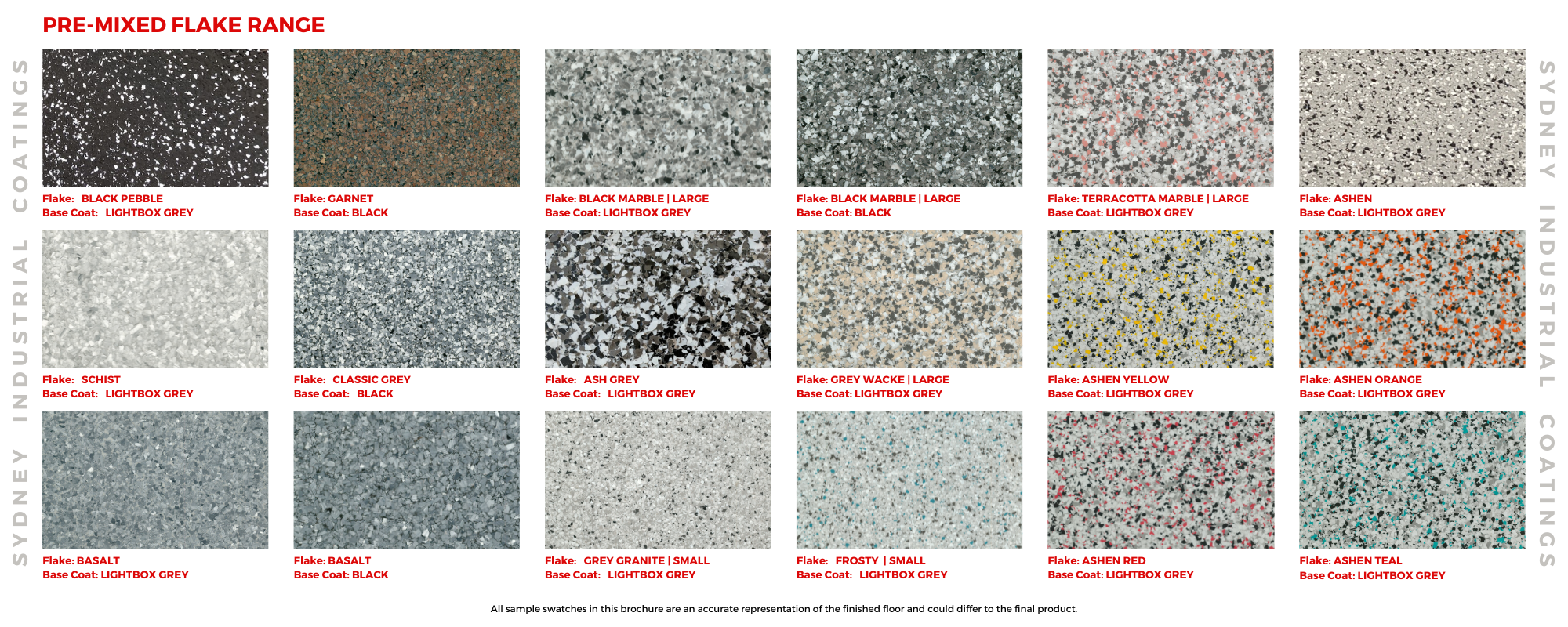

Flake Floor Coating For Garages, Shops, Showrooms, Patios, and more

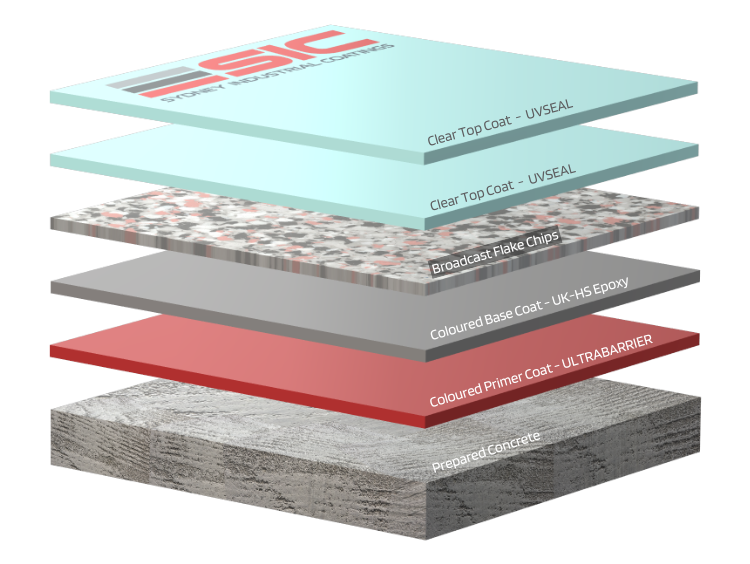

Achieve a flawless flake floor coating with Ultrakote products using our step-by-step guide. We provide all the necessary steps and products for a seamless and durable finish. Perfect for both DIY enthusiasts and professionals, our guide makes the process simple and successful. See below to find out about the process and latest pricing on products offered by UltraKote Australia.