Equipment Cost to Start an Epoxy Flooring Business!

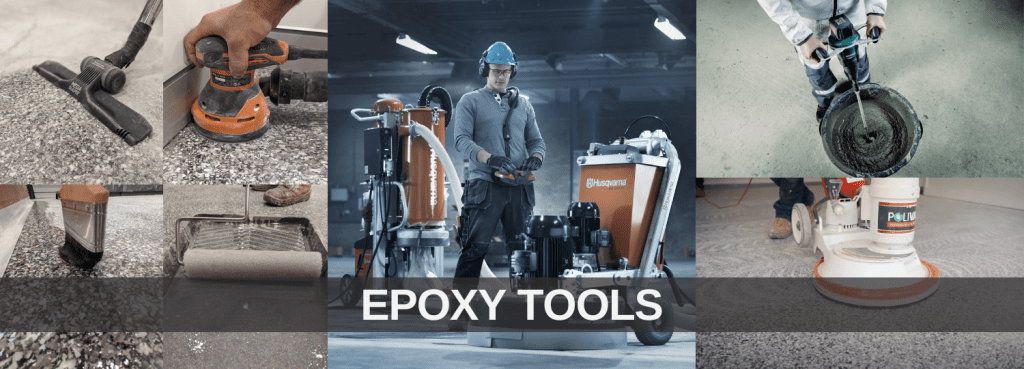

REQUIRED EQUIPMENT TO START AN EPOXY FLOORING BUSINESS

Starting a business can be both challenging and rewarding. It requires you to find the right equipment, materials, and tools to get your venture off the ground. If you’re looking to start an epoxy flooring business, then this article has all the information you need to help make your dream a reality. We will outline the exact materials that are required in order for you to begin offering professional epoxy floor coating services, and if this is something of interest to you, continue reading!

Brief talk about epoxy flooring

Epoxy flooring is one of the most durable and stylish options for both homes and businesses. It can provide floors with a glossy, smooth finish that resists damage from everyday wear and tear. Installing epoxy flooring involves:

- Preparing the concrete

- Repairing any imperfections and cracks

- Applying a primer to the surface will help bond the coating system

- Application of the desired topcoat system

The thickness of each layer varies according to its intended use, but generally, it takes time and precision to ensure a flawless finish. With professional installation, and appropriate maintenance, epoxy flooring can offer years of long-lasting protection, perfect for higher traffic areas.

List of required equipment and tools with a look into what each tool does

Correct preparation is the most essential step in applying any long-lasting floor coating system and concrete grinding or shot blasting are two common methods of preparing a surface before applying epoxy flooring.

As shot blasters cost more and are a difficult machine for beginners, we are going to discuss concrete grinders only.

Concrete grinders are machines that use diamond plugs or cup wheels and cut the top layer of concrete as the diamonds rotate. Diamond grinding can remove a variety of different containments, open the pores of the concrete, and provide a clean surface for epoxy to adhere to. PCD Diamond Grinding plugs are also an available option as they have the strength and durability to remove existing coatings on the floor.

Edge Grinders | Costs approximately $300 – $2,500

This machine is used for small grinding jobs and getting close to the edges when there is no room for bigger machines. Hilti’s & Metabo’s 125mm Angle Grinders are two of the most common machines and you can even buy the Hand Grinder from Bunnings for a better price.

Walk Behind Grinders | Cost $2,000 – $17,000

Walk behind grinders take on grinding plugs or grinding shoes and are used to grind the bigger floor spaces. As bigger machines have stronger power and better weight distribution, they tend to provide a better finish and cut faster.

Some of the most common 240-volt machines in Australia are:

- RUBICON 480mm Concrete Floor Grinder | $5,799.00 inc GST

- Scintex 250mm Concrete Grinder | $1,999.00 inc GST

- Scintex (Paddock) 480mm Concrete Grinders | $5,850.00 inc GST

Dust Extractor’s | Costs approximately $2,850 – $5,000

Dust extractors are a vital tool when it comes to concrete grinding as they provide maximum protection against the dust and debris generated during the grinding process. Not only do they protect you, and other people in the area, from breathing in potentially dangerous particles, but they also help to reduce clean-up times and costs associated with the project. Dust extractors safeguard surfaces and fabrics in the work environment by trapping dust particles instead of allowing them to accumulate around the equipment or circulate through the air. As such, investing in a quality dust extractor for concrete grinding is essential in ensuring a safe job site, protecting expensive materials and restoring clean air.

Here is a list of most common dust extractors at the time of writing this blog:

- Floorex Dustmaster 2660 Twin Loader Vacuum | $3,300.00 inc GST

- Husqvarna DE110 | $2,850.00 inc GST

Mixers / Paint Stirrers

Paint mixers or stirrers are available in both wired and cordless versions, and both types have their own advantages:

Wired stirrers have a lot more power and are good for big batch mixing jobs where large epoxy flooring kits are required. They can be purchased from Bunnings or Ozito and the cost can vary from $200 – $1,500

Mixing paddles can be attached to any 18-volt cordless drill and used as a stirrer for mixing small epoxy products. Our preferred drill is the Metabo 18-Volt Drill (with two battery packs) as it only costs $313.

Epoxy application tools and accessories | A good set up will cost about $500

Good quality professional epoxy application tools and accessories are another essential part of applying epoxy flooring which will help you deliver high quality work. The accessories needed would be as follows:

- Spike shoes

- Epoxy rollers and frames

- Extension poles

- Epoxy trays

- Gloves

Here at Sydney Industrial Coatings, our aim is to provide you with honest and correct advice, as we believe that your success, is our success. Our most important value, as a company, is to ensure you have the best chance at creating and growing your business. Nothing can bring more satisfaction than helping our clients find their passion, and if you require any further information about what has been discussed, or would like to enrol yourself in our upcoming epoxy training course, contact us today!